People were more ingenious and devised ways to efficiently do the most difficult home tasks long before technology cast single socks into a spinning purgatory.

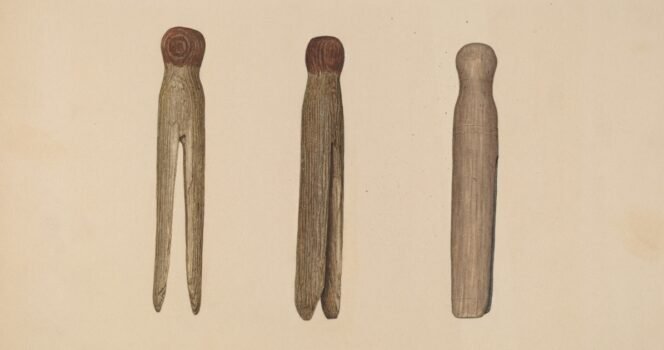

Among such tools is this wooden peg, which developed into a two-piece pin that was used to fasten objects to a line throughout time. Compared to the previous model, which fed socks and other clothing to the wind—”a serious evil to washerwomen”—this was a major improvement.

To find out more about this wooden instrument, continue reading!

A user recently discovered little, two-legged wooden dowels and turned to social media to ask for assistance in identifying the items.

With the response, “Old school clothespins,” the Facebook post drew in a generation of sentimental baby boomers. We used them to hang our freshly laundered, damp garments outside on the laundry line so they could dry in the fresh air and sunlight.

Wet laundry is traditionally hung on a clothesline to dry using a wooden clothespin, sometimes referred to as a clothes peg. These days, the pins are usually made of two hardwood pieces that are hinged together at one end. A spring mechanism gives the pins the tension they need to hold onto the garment.

The ancient past

The origins of wooden clothespins may be found in the ancient past, when people secured their clothing while it was drying using a variety of techniques.

In contrast to the wooden clothespins we are accustomed to today, the first carved clothespins were made in antiquity. Usually made by hand from natural materials like wood, bone, or even stone, these early clothespins sometimes had elaborate designs or themes.

The increased demand for a practical and efficient instrument to hang laundry led to the invention of the contemporary wooden clothespin in the 19th century.

The first clothespins were made by hand from solid wood, usually maple or birch, and had a straightforward form made up of two pieces of wood that were held together by a little spring or metal wire.

Malevolence against washerwomen

David M. Smith of Vermont patented a clothespin in 1853, which is when the standard form we use today originated.

The revised clothespins “are hinged together” by a wire “so that the two longer legs may be moved toward each other and at the same time move the shorter ones apart,” according to his patent, which was issued on October 25, 1853.

When the two wooden pieces are pressed together, their shape creates a clamp. This makes it possible for the clothespin to firmly and damage-free grasp onto clothing. Even in windy situations, the clothespin’s spring mechanism guarantees that it stays closed when in use, giving you a steady hold on the washing.

“An additional benefit and a crucial one as well, [what] my improved clothes pin has over the common pin is that it cannot be detached from the clothes by the wind as is the case with the common pin and which is a serious evil to washerwomen,” Smith clarifies in the patent.

Changing pins

The production of wooden clothespins became increasingly automated as industrialization advanced in the late 19th and early 20th centuries. The emergence of wooden clothespin manufacturers allowed for the speedier and less expensive production of huge quantities of standardized clothespins. This led to the widespread usage of wooden clothespins as a laundry tool by making them more affordable for a wider variety of homes.

Even with the advent of substitute materials like plastic, wooden clothespins continued to be a common sight in homes all across the world during the 20th century. They were a popular option for hanging washing because of their price, ease of use, and durability—especially for people without access to contemporary drying technology.

Wooden clothespins are still made today and used in homes all over the world for crafts or drying clothes. They are prized for their eco-friendliness and nostalgic charm.

Wooden clothespins continue to be a representation of conventional washing methods and eco-friendly living, even if plastic clothespins have proliferated in some areas due to their mass manufacture and reduced cost.